Release time:2025-07-16

1、 The design basis of plastic mold, dimensional accuracy and the accuracy of related dimensions, and the specific requirements and functions of the whole product of plastic shell determine which kind of appearance quality and specific size it belongs to: plastic shell with high requirements for appearance quality and important dimensional accuracy, such as toys; Functional plastic products with strict size requirements; Plastic shell with strict requirements on appearance and size, such as camera. Whether the demoulding slope is reasonable. Demoulding slope is directly related to the demoulding and quality of plastic shell, that is, whether the injection molding process can be carried out smoothly: whether the demoulding slope is sufficient; The slope should be compatible with the parting or parting surface of the plastic shell; Will it affect the accuracy of appearance and wall thickness; It will affect the strength of a part of the plastic shell.

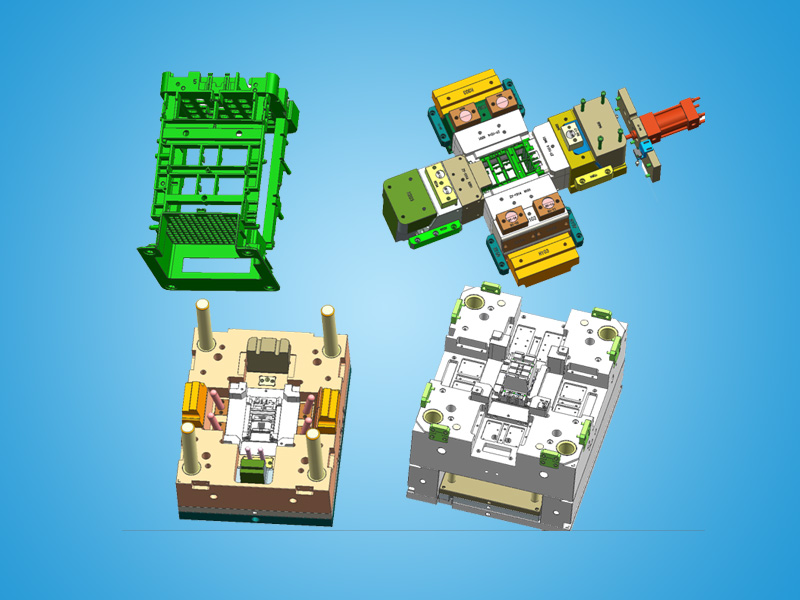

2、 Design scheme, analyze and digest plastic shell drawings and entities (real samples): geometric shape of plastic shell; Dimensions, tolerances and design basis; Technical requirements; Name and brand of plastic raw materials and surface requirements. Number and arrangement of cavities of plastic shell: weight of plastic shell and injection volume of injection machine; The projected area of the plastic shell and the clamping force of the injection machine; The overall dimension of the plastic shell mold and the effective area of the installation mold of the injection molding machine (or the inner distance of the pull rod of the injection molding machine). Accuracy and color of plastic shell; Whether the plastic shell has a side shaft core and its treatment method; Production batch of plastic shell; Economic benefits (output value of each module).

After the number of plastic shell cavities is determined, the cavity arrangement, that is, the cavity position arrangement, involves mold size, gating system design, gating system balance, core pulling (slider) mechanism design, insert and core design, and heat exchange system design. These problems are related to the selection of parting surface and gate position. Therefore, in the specific design process, necessary adjustments should be made to achieve a more perfect design.

3、 The determination of the parting surface does not affect the appearance, which is conducive to ensuring the product accuracy and mold processing, especially the processing of the cavity; It is conducive to the design of gating system, exhaust system and cooling system; It is conducive to mold opening (mold splitting and demoulding), and ensure that the product remains on the side of the moving mold when opening the mold; Facilitate the arrangement of metal inserts.

4、 The design of the gating system and the gating system design of the plastic shell mold include the selection of the main runner, the determination of the sectional shape and size of the shunt runner, the selection of the gate position, the determination of the gate form and the sectional size of the gate. When using the point gate, we should also pay attention to the design of the gate device, gate device and gate mechanism, so as to ensure the separation of the runner. When designing the gating system, the first step is to select the location of the gate. The choice of gate position is directly related to the molding quality of plastic shell and the smooth progress of injection process. The selection of gate position should follow the following principles: the gate position should be selected on the parting surface as far as possible, so as to facilitate the gate cleaning in the process of mold processing and use; The distance between the gate position and each part of the cavity should be as consistent as possible, and the tool flow should be the shortest; The position of the gate should ensure that when the plastic flows into the cavity, the width of the cavity is aligned with the thick wall part, so as to facilitate the smooth flow of the plastic; The gate shall be located at the thickest part of the plastic part; Avoid the plastic rushing directly to the cavity wall, core or insert when flowing down the cavity, so that the plastic can flow into all parts of the cavity as soon as possible, and avoid the deformation of the core or insert; Try to avoid welding lines on the product, or welding lines on unimportant parts of the product; The position of the gate and the plastic inflow direction should make the plastic raw materials flow evenly in the direction parallel to the cavity when flowing into the cavity, and be conducive to the discharge of gas in the cavity; The gate should be set at the position where the plastic shell is most easily removed, and at the same time, it should not affect the appearance of the product as much as possible.

5、 The design of exhaust system plays an important role in ensuring the molding quality of plastic shell. By using the exhaust slot, the exhaust slot is usually located in the last filled part of the cavity. The depth of the exhaust slot varies with different plastics, which is basically determined by the maximum allowable gap of plastic without flash. For example, abs0.04 mortar is less than 0.02 mm, and steel is less than 0.02mm. Exhaust by using the fitting clearance of the plug-in push rod or the special exhaust plug; Sometimes, in order to prevent the plastic shell from vacuum deformation during ejection, it is necessary to use an air pin. Sometimes, in order to prevent vacuum adsorption between the plastic shell and the mold, anti vacuum adsorption parts are designed.

6、 The design of cooling system for plastic shell mold is a complex work. We should not only consider the cooling effect and uniformity, but also consider the impact of the cooling system on the overall structure of the mold. Including the layout of the cooling system and the specific form of the cooling system; Determine the specific location and size of the cooling system; Cooling of key parts, such as moving dies or inserts; Cooling of side slider and side core; Design of cooling elements and selection of cooling standard elements; Sealing structure design.